WARNING

Proper operation of your brakes is essential for your safety and the safety of others. Any brake service should be performed ONLY by persons experienced in the installation and proper operation of brake systems. It is the responsibility of the person installing any brake component or kit to determine the suitability of the component or kit for the particular application. After installation and before operating your vehicle, be sure to test the function of the brakes under controlled conditions. DO NOT DRIVE WITH UNTESTED BRAKES!

IMPORTANT

Take time to read all the literature that came with this kit. Check the provided list of parts against what you received to ensure all parts are present. While this kit was designed to make the process of changing brake parts as simple as possible. NOTE: WITH SOME KITS IT MAY BE NECESSARY TO MAKE MINOR CHANGES TO YOUR CAR!

READ ALL WARRANTY DISCLAIMERS AND RETURN POLICIES INCLUDED IN THIS KIT PRIOR TO INSTALLATION!

NOTE:

Before operating the vehicle after installation, test the function of the brakes under controlled conditions. Make several stops in a safe area from low speed and gradually work up to normal speeds. DO NOT DRIVE WITH UNTESTED BRAKES! Always utilize safely restraints when operating the vehicle.

Will not fit 292/312 engines with the original exhaust manifolds or big block cars from 1957-59.

Booster Kit includes the following components:

- Power booster with firewall bracket and pedal linkage.

- Dual outlet master cylinder

- Bench bleeding kit. (Included with master cylinder)

INSTALLATION

- Disconnect the master cylinder push rod from the pedal inside the vehicle.

- Remove the brake lines from the old master cylinder.

- Remove the old master cylinder.

- Mount the new booster to the four studs on the firewall with the bracket oriented as above.

- Connect the booster push rod to the pedal using the existing hardware. Adjust the push rod to have approximately 1/4” free-play at the top of the pedal.

- Bench bleed the new master cylinder.

- Install the new master onto the booster.

- Connect the vacuum hose from the booster check valve to either the back of the carburetor or to the intake manifold with the supplied manifold fitting.

- Connect the hydraulic lines as required. The line to the rear should go to the master cylinder outlet closest to the booster.

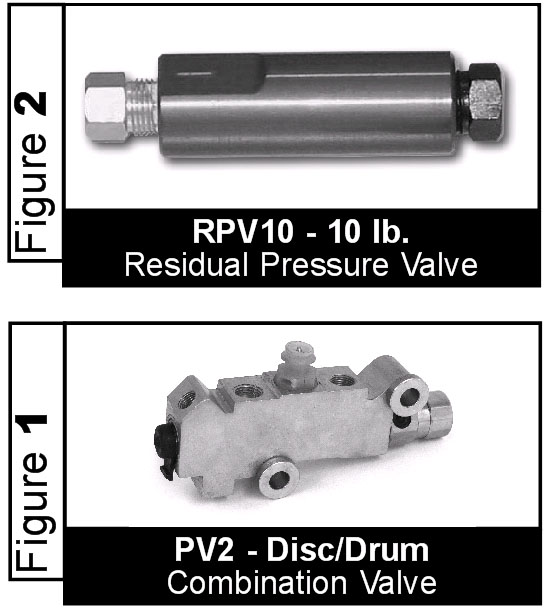

- If you have disc brakes in the front you should use a dis/drum combination valve to balance the system (Figure 1).

- The lines for drum brakes may be run directly with one line to the front and one line to the rear. As above the line closest to the booster should feed the rear drum brakes.

- Also drum brakes will require the use of a 10 lb residual valve to the front and a 10 lb residual valve to the rear (Figure 2).

- Bleed the entire braking system before operating. Check the pedal for firmness. If pedal is not firm bleed system again.

I would like the price for the following item: Ford Power Brake Pedal Assembly. Also, will this fit in a 1964 Ford Galaxie 500?

Thank you.

The booster unit in question will work on your 1962 Ford Galaxie 500. Here is the link to the item on our store!

http://www.performanceonline.com/1952-72-FORD-AND-MERCURY-FULLSIZE-CAR-POWER-BRAKE-BOOSTER-KIT-19528/

need a disc brake conversion kit for a 1959 Ford 2 door Ranch wagon. Laso will this power brake system fit same vehicle.

Please contact us via our normal sale email at sales@performanceonline.com

will this set up work on a 1955 ford mainline with wildwood front disc and is the brake switch a pressure switch or a mechanical switch on the pedal assembly

Hi Saul. Yes this kit will work for your application, The prop valve comes with a low pressure brake light “warning” switch, We do sell the pressure brake light switch part number BLS-00

https://www.performanceonline.com/1948-64-ford-f-1-f-100-brake-light-switch-bls-00/