Manufacturers recommend replacing your brake fluid every three years or so because most fluid deteriorates with use. Also, its affinity for water reduces the fluid’s heat resistance and can cause brake-system corrosion.

An essential part of replacing brake fluid is bleeding the system. While bleeding sounds as if leeches and a medieval barber might be involved, here it just means ridding the brake system of trapped air, something anyone handy with tools can accomplish at home with an able assistant.

WHAT YOU’LL NEED:

- BOX END WRENCH(USE APPROPRIATE SIZE)

- BRAKE FLUID(CHECK YOUR CAR’S REQUIREMENTS)

- FLUID HOLDER AND TUBING(SHOULD BE AVAILABLE AT MOST AUTO PARTS STORES)

- ASSISTANT(A FRIEND TO SAY ” PRESSURE”)

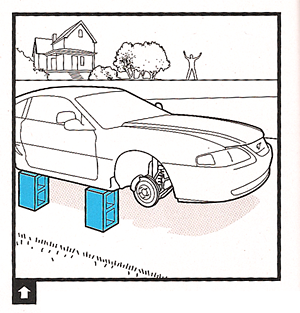

STEP ONE: Jack up the car and support it with jack stands. ( cinder blocks are the preferred alternative for those who want to ruin their neighbors’ property values.)

STEP ONE: Jack up the car and support it with jack stands. ( cinder blocks are the preferred alternative for those who want to ruin their neighbors’ property values.)

STEP TWO: Remove all four wheels.

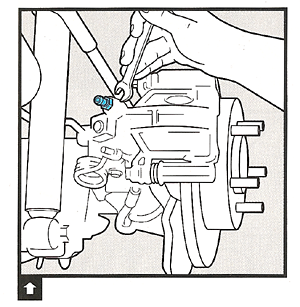

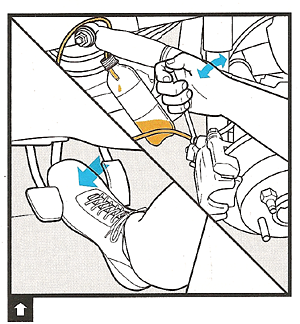

STEP THREE: Locate the caliper bleeding screws, spray them with penetrating oil, and attempt to loosen them. If they snap off or strip, stop at once and summon the aid of a professional. Then, if possible, retighten all bleeder screws with care.

STEP THREE: Locate the caliper bleeding screws, spray them with penetrating oil, and attempt to loosen them. If they snap off or strip, stop at once and summon the aid of a professional. Then, if possible, retighten all bleeder screws with care.

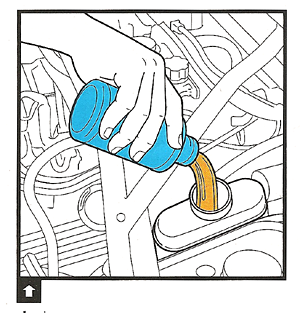

STEP FOUR: If it’s safe to proceed, check the fluid level in the brake master cylinder. Add fresh fluid if it;s lower than the marked “full” point. Use the specific type of fluid recommended in the owner’s manual because there are several different kinds and not all of them play well together. During brake bleeding, the master cylinder cap should be left unscrewed but still in place atop the reservoir.

STEP FIVE: Each brake must be bled in the correct sequence. The general format is to bleed the brake most distant from the master cylinder first, but some cars require a different order. That information is available in the factory manual or from your dealer’s service department.

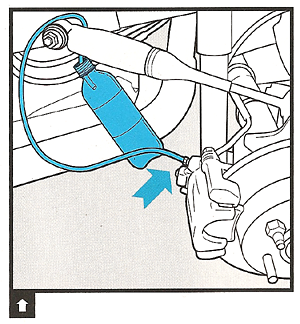

STEP SIX: Fit one end of a piece of clear tubing tightly over the bleeder screw and put the other end into a catch container. A plastic 20-ounce soda bottle works well here. To discourage air from returning to the system through an open bleeder screw, hang the catch container well above the caliper.

STEP SIX: Fit one end of a piece of clear tubing tightly over the bleeder screw and put the other end into a catch container. A plastic 20-ounce soda bottle works well here. To discourage air from returning to the system through an open bleeder screw, hang the catch container well above the caliper.

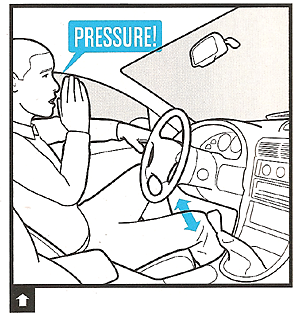

STEP SEVEN: With the car’s engine off, have your able assistant pump the brake pedal for several strokes until he or she notice resistance underfoot. The assistant should shout out “Pressure!” when a firm pedal is achieved. (You may also use whatever safe-word you and your companion have worked out from earlier encounters.)

STEP SEVEN: With the car’s engine off, have your able assistant pump the brake pedal for several strokes until he or she notice resistance underfoot. The assistant should shout out “Pressure!” when a firm pedal is achieved. (You may also use whatever safe-word you and your companion have worked out from earlier encounters.)

STEP EIGHT: While the assistant maintains pressure on the pedal, open the bleeder screw a small amount. Fluid will pass through the clear tube, and the pedal will begin dropping toward the floor.

STEP EIGHT: While the assistant maintains pressure on the pedal, open the bleeder screw a small amount. Fluid will pass through the clear tube, and the pedal will begin dropping toward the floor.

STEP NINE: Before the pedal reaches the floor, the assistant must yell “Floor!” Quickly close the bleeder screw when you hear the warning. Look under the hood and recheck the reservoir’s fluid level; add brake fluid if necessary.

STEP TEN: Repeat steps 7-9 at least five times until the stream of fluid flowing through the clear tubing is free of air bubbles.

STEP ELEVEN: Repeat steps 7-10 at the remaining three brake locations in proper sequence.

STEP TWELVE: While the assistant applies full effort to the brake pedal followed by an abrupt release of that effort, observe the motion of the fluid in the master cylinder reservoir. If there is a substantial fluid eruption, there are air bubbles still trapped in the system. You must repeat the bleeding procedure to remove that air. A modest disturbance in the fluid returning to the reservoir indicates a properly bled brake system.

STEP THIRTEEN: Double check that all bleeder screws are tight before installing the car’s wheels. Failure to complete this step will likely result in an unplanned trip to a medieval barber.