When it comes to performance, most enthusiasts gravitate to the powertrain, doubling or tripling their horsepower, installing racing transmissions, or performing extensive upgrades. Although it shouldn’t be, a lot of times the factory braking system is deemed “ok for now,” However, in almost all cases, that’s not a good plan of attack. Technology has marched on quite a bit since most classics were new, and your ride’s factory manual drum brake system probably isn’t the hot ticket a half-century later. It’s time for a brake upgrade.

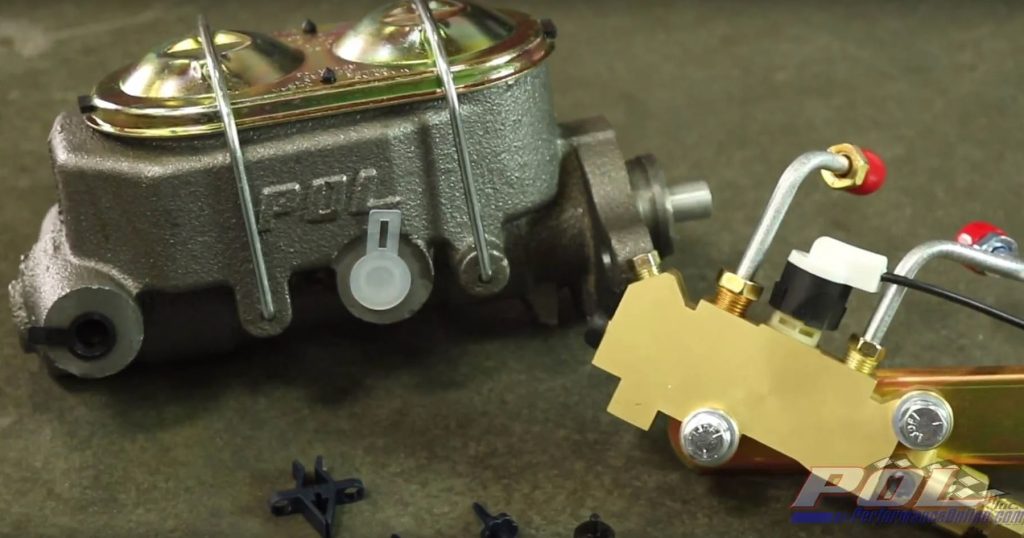

We planned to cover master cylinder design (different size pistons and reservoirs) and take into consideration what master cylinder should be used with what prop valve and caliper. We also wanted to get into proper brake bias, and selecting the right brake pads for the driving intended. After speaking with our experts at Performance Online POL, we learned the average enthusiast does not need to worry about all that, as complete kits are already designed with those considerations already, well, considered.

Where to Start: The Vehicle’s Intended Usage

The first thing we learned is, that probably the single most important part of designing a brake system is to have a plan. The pedal, master cylinder, booster, calipers, rotors, brake lines, pads, and everything else must work in conjunction with one another for optimal performance. A braking system designed for a drag racing vehicle might not work so well in a street car (or truck) and probably won’t work at all in an autocross or road racing application. The same goes for a serious set of Pro Touring brakes—you might not need them for your restomod with a 400-horsepower LS engine that will mostly see freeway driving. You have to be honest with yourself about how you’re going to use the car, and trying to cobble together parts from different areas of performance usually won’t work either.

Packaging Concerns

Another question you have to ask yourself is: will the brake setup I want work on my vehicle? Oftentimes, huge performance-oriented brake systems require larger wheels and tires, and you might not want that. Your vehicle might be equipped with a rowdy camshaft that isn’t power-brake friendly. Other aspects of your vehicle (engine, suspension, etc) might simply be in the way. It’s for these reasons companies that manufacture aftermarket brake kits often have different styles of kits for the same application (say, ’67 through ’69 Camaro).

Building A Street Driver/Restomod Braking System

Probably one of the more common brake changes involves upgrading the factory disc brakes, or switching over from old (and heavy) drum brakes to a disc brake setup. If you’re looking at replacing your factory setup or upgrading to a different style of brake system, now is the time to start looking into replacing that old and crusty factory hardware. For some information on basic upgrades, Performance Online steered us through some of the questions we had regarding building a new brake system.

Our first question of course was: why consider a brake upgrade? Well, in addition to the factory components being decades old, there is also the matter of performance. In most classic vehicles, factory brakes were designed to stop your car to avoid a collision and work well under normal driving circumstances. Performance brakes on the other hand are designed to stop the car from higher speeds repeatedly and without fade. In other words, are pretty much all-around better, especially when considering the increase in horsepower most modified classics receive.

To this end, POL had a few suggestions on how we could improve braking performance. For basic upgrades, larger-diameter disc brakes are sort of a no-brainer, and it’s easy to find everything from basic conversions, to kits with drop spindles for lowering the car), to performance brake kits from companies like Baer and Wilwood that improve 60-0 mph stopping distance, especially after repeated stops are performed. For this type of performance, one of POL’s Black Out Series brake kits would be an excellent choice.

Drag Racing Brakes (Or, Time to Get Light!)

There are plenty of street cruisers out there, but when we begin to discuss drag racing, we get more into an application-specific design of brakes. For drag racers, light makes might, so one of the big considerations to upgrading a drag car to a racing brake system is weight. It’s not uncommon for instance, for a racing set of calipers and brakes to take 20, 30, or even 40 pounds off a front brake system alone. In the case of Wilwood’s Dynalite rotor and caliper, for instance, the combination of both components weighs less than 10 pounds!

Another common option here is a rearend swap, for ultimate strength. If you have a (gulp) 9-inch, there are rear disc brake conversions that are both light, and provide excellent stopping power. Also if you’re still all-GM, they have you covered there too for rear disc kits. As drag racers know, losing weight on your car is hard, and it often takes thousands of dollars of engine parts or fiberglass to shave 60 or 80 pounds. Front and rear brakes are easy pickings.

Finally, in many drag applications, folks run manual brake master cylinders to (again) save weight. That doesn’t mean there aren’t other options, however. Your turbo car might need dual rear calipers in the rear to help stage, you may want to run a larger bore master cylinder for more pressure, or a multitude of other options for optimal performance. Pads will also often need to stop the vehicle from insane speeds with little-to-no heat in the system.

Brakes For A Serious Pro Touring Effort

There are certain cars that are designed almost exclusively for road racing, autocrossing, and other activities that involve extremely hard acceleration and braking. The question is, what if you want your base-model Camaro or Nova to do that too? Well, as it turns out, your ’60s or ’70s muscle car can, with some help. For this type of application, special attention must be paid to the brakes since they’re used so much. We feel something like a 13-inch Blackout conversion by Baer would be the hot ticket here, as performance Pro-Touring cars have a lot of added weight in wheels and tires, and it takes a lot to stop that over and over.

In power-assisted applications, performance master cylinders, vacuum pumps (that can provide vacuum boosters vacuum at all times) or a hydroboost setup that is run off of your power steering system are all valid choices when it comes to creating the best performance for autocrossing or road racing. A Pro-Touring effort is perhaps the most complicated of braking systems and is also one of the most effective if you’re looking for the best of everything.

Selecting The Right Brake Pad

Just like the rest of the braking system, brake pads can be individualized to the application for maximum performance. If you’re looking for an all-around pad that has decent performance, is quiet, and is relatively dust-free, it’s hard to go wrong with an OEM-compound pad. There are improvements to be had, however. Performance Online does offer a selection of brake pads, including its GM D52 Ceramic brake pads, which don’t produce the black metal dust of a metallic pad, yet offer a 7-percent decrease in stopping distance.

For most street-driven applications we’d consider this to be a great selection, although there are a wide number of track-day pads that can operate at temperatures up to 1,400 degrees, or drag racing pads, which are designed to aggressively stop without any type of warm-up. For heavy vehicles or applications that are under consistent heavy braking, semi-metallic pads can be used, and are available in a variety of levels of aggression. These pads do often come at the price of noise and can be fairly loud under light braking. Remember, it doesn’t hurt to ask questions, and a brake tech can usually tell you if you need something other than an OEM or upgraded pad. If you would like more information about brake pad selection, you need to click here.

Closing Thoughts: Think Twice, Buy Once

Planning a well-thought-out brake upgrade will no doubt be a great addition to your ride. It’s also one of the only upgrades that can save the ride you’ve put thousands of dollars and hundreds of hours into building when some jerk cuts you off. Talk to experts and fellow racers, and see what they like, don’t like, and what works for them. And although we did an application-based article, don’t get too hung up on it if a different design is something you really want. Your drag racing brakes will probably work fine (at least once) on the autocross. Want the biggest brakes you can find for your show car? Go ahead and buy ’em. We wanted to offer a 2+2=4 article on brakes, but it’s simply not like that. Just like engines or transmissions or chassis work, a braking system is as individualized as any other car process. So go pick the system that’s right for you.