Leaf springs are suspension springs generally used in automobiles since 1970’s production of vehicles. These springs are typically made of one or more flexible, thin, and flat steel strips that are linked together to make it work as a single unit. These steel strips that make one leaf spring are shaped like an arc. Its ends are attached to the bottom of a vehicle to support and help position the axle, as well as absorbing shocks.

There is methodology and science involved in the construction, usage, and installation of these leaf springs. The vehicle’s performance on the road depends largely on the installation and the type of leaf spring used. Leaf springs come in two basic forms, the multi leaf and mono leaf.

Mono-leaf Springs

Mono-leaf springs have one arc-formed steel strip that is thicker in the middle and thin on the ends. They are usually branded as low-rate thin leaf springs that work in locating rear ends. Basically, they substitute the Panhard bars and trailing arms used in three and four links systems.

Mono-leaf springs provide lesser spring rates that hold a vehicle up. They also offer lesser stiffness in terms of bending and controlling the axle wrap-up. A vehicle’s design should include extra leaf springs, third link, and lift bar system for added support in controlling accelerating forces that rotate the rear ends.

Multi-leaf Springs

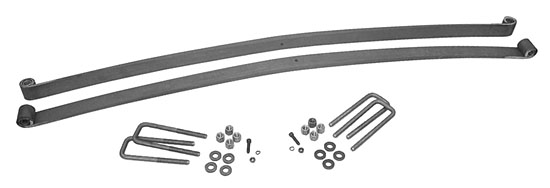

Multi-leaf springs are made of a number of arc-formed steel strips. These steel strips come in various sizes that are joined with the shortest steel strips at the bottom and the longest steel strips at the top. Generally, multi-leaf springs can support greater loads compared to the mono-leaf springs. They provide higher spring rates for bumps and lesser rates for rebounds, which are both useful in supporting and controlling a vehicle’s axle wrap-up. Moreover, it offers better car performance and endurance.

Advantages of Using Leaf Springs

A leaf spring suspension provides more tolerance to tacky and rough roads. It allows the car to perform in consistent conditions. It supports chassis weight and efficiently controls chassis roll by employing wide spring base and higher rear moment center. When the vehicle is not mounted, it controls rear end wrap-ups, axle stifling, and braking forces. Like a Panhard bar, it controls lateral forces with less lateral movements. When under acceleration and braking, it reduces rear steer while maintaining wheelbase lengths.

For a perfect vehicle performance and ride height, as well as freshening up a worn-out suspension, install new F-100 leaf springs. It is one great way to prevent axle wrap and provides better vehicle stability and cornering. For more ride height or lower stance, use a small block kit to help level out the ride and get rid of any problems that may arise. Mostly, F-100 leaf springs come with complete leaf pack kits that contain separate leafs for future use, and they all are ready to install.

when puting 5″lowering leaf springs on a 83 chevy truck

do you put them on top of axl or under the axl ?

The 5″ lowered leaf springs would be installed in the factory position which would be on

top of the rearend for the 1983 Chevy Truck.

i have 8′ rim with tire 9′ stock mono leaf spring hit tire i may can get 1/2 ‘ if i trim the out side have not got rear end help please

Please contact us via email at info@performanceonline.com

Hi

I need drop leaf front springs

do you have 4″ and 3″?

How much is the price and the shipping costs to Austria?

Regards Andre

Hello, We should have what you need. We also need more information from you. Please contact us at info@performanceonline.com