WARNING: Installation of any component or kit should only be performed by someone experienced in the installation and proper operation of brake systems. It is also the responsibility of the person installing any brake component or kit to determine the suitability of the component or kit for that particular application.

NOTE: Before operating the vehicle after installation test the function of the brakes under controlled conditions. Make several stops in a safe area from low speed and gradually work up to normal speeds. DO NOT DRIVE WITH UNTESTED BRAKES! Always utilize safety restraints when operating the vehicle.

STEP A: Be sure to check that your kit has all the necessary parts needed to complete this project! (Use the supplied parts list as a check list.) Also check that you have the correct tools for this project!

STEP B: Remove the following components from your car:

Tech tip: Prior to disassembly spray the nuts and bolts that you will be removing with a penetrant. (Also disconnect the battery to eliminate the risk of draining the battery or an electrical short.)

- Disconnect the brake lines to the master cylinder.

- Next, remove the push rod and linkage from the brake pedal.

- Then remove the old manual master.

STEP C: Things to prepare before assembly of the new booster and master kit.

- Measure 3″ to rear and mark frame side rail directly behind and at same height as pedal pivot. Center pivot bracket on mark and check clearance to floor. (Lower mark if needed.) Drill 1/2″ hole.

- Remove the new master cylinder from the booster assembly. (If applicable.)

- Bench bleed the new master cylinder to remove all the air. If all the air is removed from the master, then it will be difficult to push the piston in.

How to bench bleed:

- Remove the master from the booster and place in a vice. (Be sure to clamp onto the mounting ear and not the cylinder.)

- Install the proper size plugs in the outlet ports of the master.

- Fill the master cylinder to the full line with brake fluid.

- Use a rounded end rod or a phillips head screw driver and push the piston in repeatedly until no bubbles are visible.

NOTE: This may take a minute or two of continuous pumping!

STEP D: Installation of pedal components & booster – master unit.

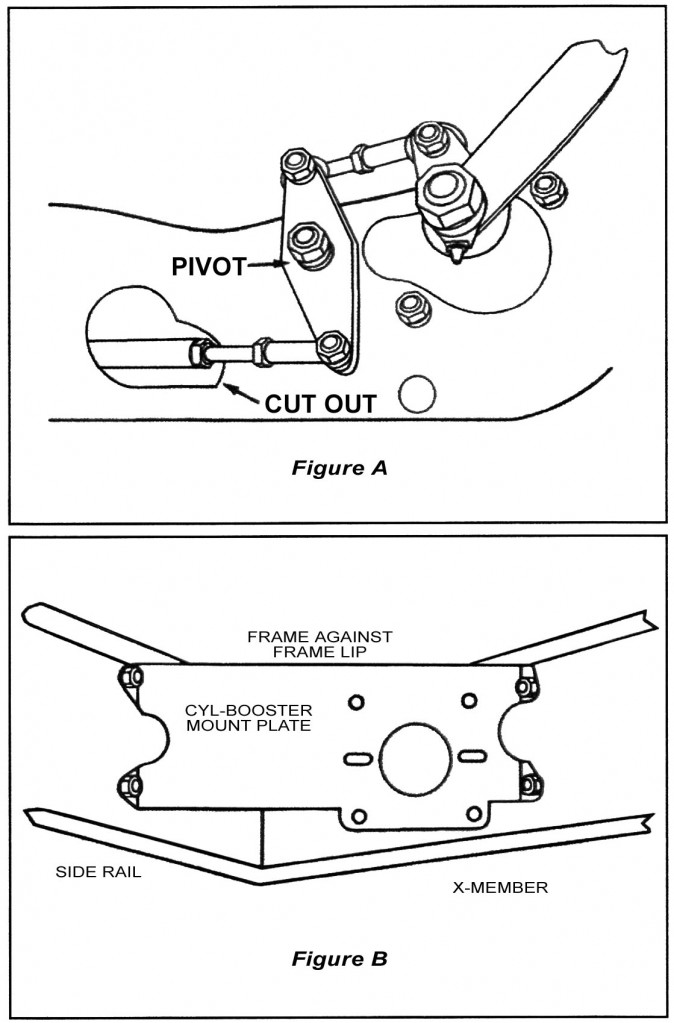

- Bolt linkage pivot stud to rail (See Figure A). Install linkage pivot bracket onto stud with longest side of bushing toward frame rail.

- Install the master cylinder/booster mount plate between outer side frame rail and X-member, with the tabs facing to the rear. The upper outer tab, may use the existing hole in some frames. The lower inner tab rests on lower X-member lip. Square the bracket on the frame and clamp into place. Drill through tabs into frame and install bolts. May remove trans X-member for access to upper bolt through X-member (See Figure B).

- Install upper linkage rod to pedal arm (drill pedal hole out to 3/8″) and to linkage pivot bracket with rod ends on frame side. Mark frame hole for enlargement and cut out for lower linkage clearance as shown (See Figure A).

- Master Cylinder ONLY: Screw pushrod into linkage end and then bolt the master cylinder to plate. Adjust linkage to allow pedal arm to fit within 1/8″ of toe/floor board.

- Booster/Master Cylinder Combo: Screw booster linkage to pedal linkage rod and bolt booster and cylinder to mounting plate. Adjust linkage to allow pedal arm to fit within 1/8″ of toe/floor board.

STEP E: Installation of brake lines and valving.

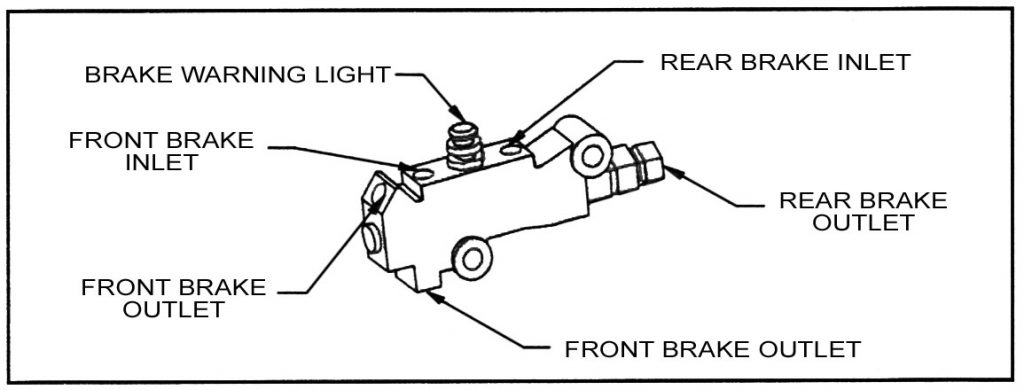

- Attach the brake lines to the master. If your kit came with a combination valve go ahead and install it, as per the supplied valve kit instructions. Note: It is important to remove any factory installed valves from the system. Failure to do so could result in a nonfunctional brake system.

- On vehicles which had a single outlet master cylinder you will need to install a new hard line from the proportioning valve outlet to a “T” fitting and then on to the rear wheels. There are two oulets for the font wheels on the combination valve. You have the option of running a line from each wheel to each outlet or running both lines to a “T” fitting and then one line into one of the outlets. (In this scenario, you will have to plug the unused outlet.) Either way is acceptable and neither routing has improved braking performance over the other. (Be sure to keep all lines away from exhaust, steering or other things that could harm them.)

- When the valve is plumbed correctly and all hard lines are attached, bleed the entire system.

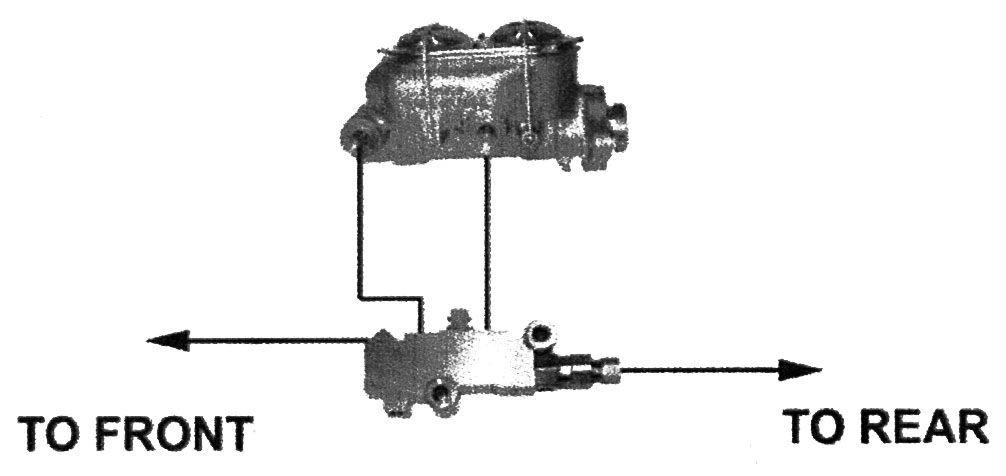

- If you are not using a combination valve, or you have four wheel drum brakes, you will need to run one line from the master cylinder to the front and one to the rear. The outlet furthest from the booster will feed the front brakes. We recommend that you use a 10lb residual valve on both the front and rear drum brakes to provide a firmer pedal feel.

- Reconnect the battery and start the engine. Test the brakes. If the pedal goes to the floor or is very spongy then bleed the system once again.

- Test drive the car in a safe location before driving.

PARTS LIST:

- (1) Booster Bracket

- (1) Rod

- (2) 3/8 x 24 RH Heim Joint (Male)

- (1) 3/8 x 24 RH Heim Joint (Female)

- (3) 3/8 x 16 x 1 1/2 GR.8 w/nylox, thick washer and flat washer

- (1) 1/2 x 20 nut GR.5 lock

- (1) 1/2 Flat Washer

- (1) 7/16 x 20 nut

- (1) 7/16 Flat Washer

- (1) 7/16 Lock Washer

- (4) 5/16 – 18 x 1 1/4 GR.5 bolt

- (4) 5/16 – 18 nut

- (4) 5/16 Flat

- (4) 5/16 Lock